The textile industry has long relied on advanced yarn solutions to meet the evolving demands of performance, versatility, and sustainability. Among these innovations, the FDY flat yarn series has emerged as a critical component in modern textile manufacturing, offering unique properties that enhance both production efficiency and end-product quality.

Understanding the FDY Flat Yarn Series

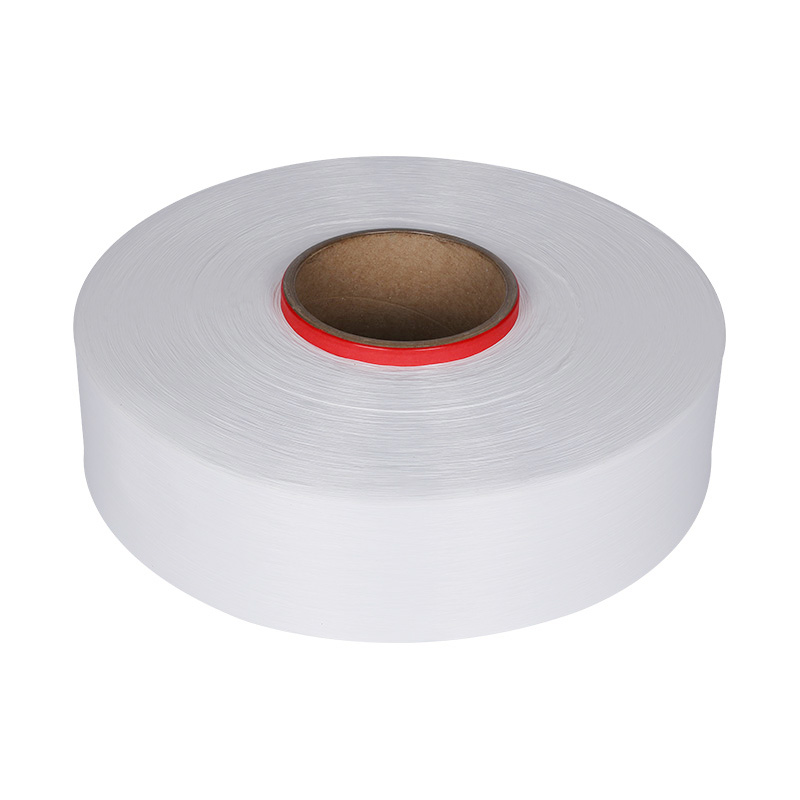

FDY, or Fully Drawn Yarn, refers to a type of filament yarn that is drawn during extrusion to achieve desired molecular orientation and strength. The flat yarn series is characterized by its smooth, uniform surface, consistent denier, and high tensile strength. These properties make it highly suitable for diverse textile applications, ranging from apparel fabrics to technical textiles.

Key Characteristics

The FDY flat yarn series is distinguished by several core attributes:

| Attribute | Description |

|---|---|

| Uniformity | Maintains consistent thickness and surface smoothness, reducing defects during fabric production |

| Strength | High tensile strength allows for durable fabrics suitable for both apparel and industrial use |

| Elasticity | Moderate elasticity ensures flexibility without compromising dimensional stability |

| Luster | Smooth surface enhances the visual appeal of fabrics |

| Dye Affinity | Good dye uptake results in vibrant and uniform colors |

These characteristics collectively make the FDY flat yarn series an essential choice for manufacturers seeking a reliable and versatile yarn solution.

Production Process of FDY Flat Yarn

The production of FDY flat yarn involves several stages, each designed to optimize fiber orientation and performance. The process begins with polymer extrusion, followed by a precise drawing stage, and concludes with winding and packaging.

Polymer Extrusion

Polyester or other synthetic polymers are melted and extruded through spinnerets to form continuous filaments. The extrusion process is carefully controlled to ensure uniform filament diameter, which is crucial for achieving consistent yarn quality.

Drawing

The extruded filaments are then drawn to align the molecular chains, enhancing tensile strength and elongation properties. This stage is critical for the flat yarn series, as it defines the smoothness and uniformity of the final product.

Winding

After drawing, the filaments are wound into packages suitable for textile processes such as weaving, knitting, or circular knitting. Proper winding ensures minimal yarn tension variations, reducing the risk of breakage during downstream processing.

| Stage | Purpose | Key Outcome |

|---|---|---|

| Extrusion | Form continuous filaments | Uniform diameter |

| Drawing | Align molecular chains | Increased strength and elasticity |

| Winding | Prepare for textile use | Reduced tension variations |

Applications of FDY Flat Yarn Series

The versatility of the FDY flat yarn series allows it to be used in a wide range of textile applications. Its unique combination of strength, smoothness, and luster enables high-quality fabric production across multiple sectors.

Apparel Fabrics

FDY flat yarn series is widely used in apparel fabrics due to its smooth texture, good draping properties, and excellent dyeing performance. It is suitable for garments such as shirts, blouses, dresses, and sportswear, where both appearance and comfort are critical.

Technical Textiles

In technical textiles, FDY flat yarn series provides the necessary strength and stability for applications such as industrial fabrics, geotextiles, and upholstery. Its high tensile strength ensures durability under demanding conditions, while its smooth surface facilitates advanced finishing processes.

Knitting and Weaving

The consistent diameter and smoothness of the FDY flat yarn series make it ideal for both knitting and weaving operations. In weaving, it contributes to fabric uniformity and reduces machine downtime, while in knitting, it ensures even stitch formation and fabric elasticity.

| Application | Benefits | Typical Products |

|---|---|---|

| Apparel fabrics | Smooth texture, good draping, vibrant colors | Shirts, dresses, sportswear |

| Technical textiles | High strength, dimensional stability | Industrial fabrics, geotextiles |

| Knitting & weaving | Consistent diameter, reduced defects | Woven and knitted fabrics |

Advantages of FDY Flat Yarn Series in Manufacturing

Adopting the FDY flat yarn series in textile production offers multiple operational advantages:

Efficiency: The uniformity of the yarn reduces machine stoppages and waste, improving overall production efficiency.

Fabric Quality: Consistent yarn properties translate into high-quality fabrics with better visual appeal and performance.

Flexibility: Compatible with various textile processes, including weaving, knitting, and circular knitting.

Customization: Available in different deniers and luster levels to meet specific fabric requirements.

Comparative Overview

The FDY flat yarn series stands out compared to other yarn types due to its unique combination of properties. Below is a simplified comparative table highlighting its advantages:

| Feature | FDY Flat Yarn | Other Filament Yarns |

|---|---|---|

| Surface Smoothness | High | Moderate |

| Tensile Strength | High | Varies |

| Dyeing Performance | Excellent | Moderate to Good |

| Application Versatility | Wide | Limited in some sectors |

| Production Efficiency | High | Variable |

Conclusion

The FDY flat yarn series represents a strategic solution for modern textile manufacturing, balancing strength, smoothness, versatility, and dyeability. Its broad application range—from apparel fabrics to technical textiles—combined with operational efficiency and emerging eco-friendly trends, positions it as a key material for industry advancement. Manufacturers seeking to enhance fabric quality and production performance can benefit significantly from integrating the FDY flat yarn series into their operations.

FAQ

Q1: What makes the FDY flat yarn series different from other FDY yarns?

A1: The flat yarn series is distinguished by its smooth surface, consistent diameter, and high tensile strength, providing superior fabric uniformity and dyeing performance.

Q2: Can FDY flat yarn series be used for both knitting and weaving?

A2: Yes, its uniformity and strength make it compatible with a variety of textile processes, including knitting, circular knitting, and weaving.

Q3: What types of fabrics benefit most from FDY flat yarn series?

A3: Apparel fabrics, sportswear, technical textiles, and industrial fabrics all benefit from its smoothness, durability, and color consistency.

Q4: Are there sustainable options within the FDY flat yarn series?

A4: Yes, FDY yarns produced from recycled or bio-based polymers are increasingly available, supporting environmentally conscious textile production.

Q5: How does FDY flat yarn series improve manufacturing efficiency?

A5: Its consistent quality reduces machine stoppages and defects, minimizes waste, and ensures reliable fabric formation, boosting overall production efficiency.

+86-0571-82795522

+86-0571-82795522

LANGUAGE

LANGUAGE

English

English