In the textile industry, innovation is key to improving the performance and durability of fabrics. One of the most promising advancements in this field is the development of composite differentiated yarns. This new class of yarn combines multiple materials or fibers in varying proportions, offering unique benefits in terms of strength, flexibility, and wear resistance.

Introduction to Composite Differentiated Yarn

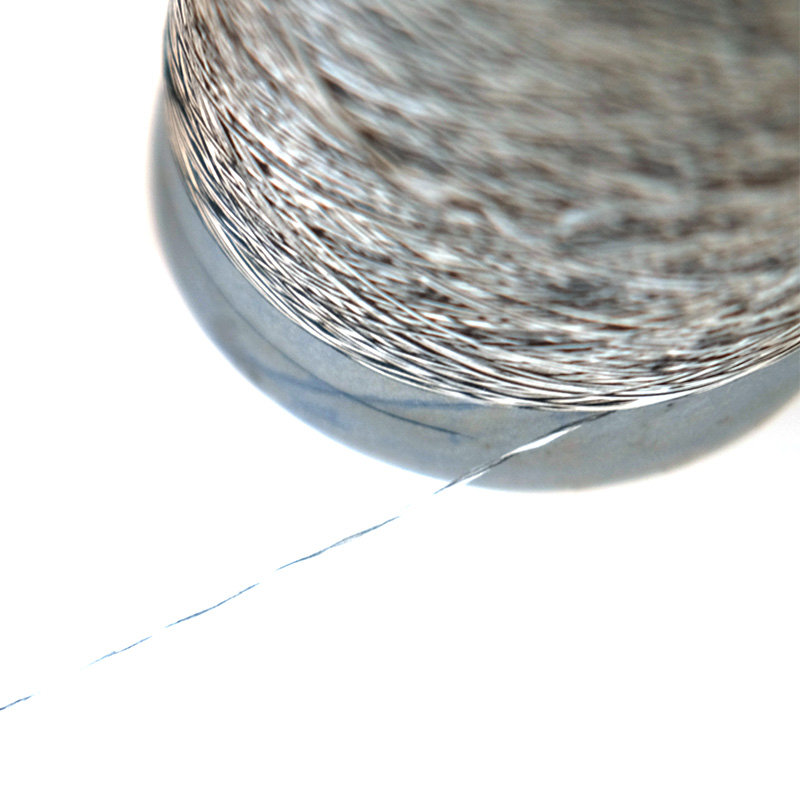

Composite differentiated yarn is created by blending different types of fibers, each contributing its own unique properties to the finished product. These yarns are designed to offer superior performance compared to conventional single-fiber yarns. By combining fibers such as polyester, nylon, cotton, or natural fibers with synthetic materials, composite differentiated yarns can achieve a balance of strength, elasticity, moisture-wicking ability, and resistance to wear and tear.

The concept of differentiated yarn refers to the variation in the structure and composition of the yarn, which can include multiple types of filaments or fibers with distinct properties. These variations are engineered to address specific requirements in fabric performance, such as high tensile strength, increased durability, and moisture management.

Key Benefits of Composite Differentiated Yarn

Enhanced Durability

One of the most significant advantages of composite differentiated yarn is its ability to significantly enhance the durability of fabrics. Traditional yarns made from a single fiber type often wear out more quickly due to their uniform properties. However, composite yarns, with their multi-fiber structure, resist abrasion and damage much better. This is particularly beneficial in high-stress environments where fabrics are subjected to constant friction, such as in outdoor clothing, industrial textiles, and upholstery.

Improved Performance Under Different Conditions

Composite differentiated yarns excel in various performance parameters. For instance, when blended with moisture-wicking fibers, they can create fabrics that are highly effective at drawing moisture away from the body, making them ideal for sportswear and activewear. Similarly, when combined with elastic fibers, composite yarns can produce fabrics with improved stretchability, providing comfort and flexibility without compromising strength.

Versatility in Applications

Thanks to the wide range of fibers that can be combined in composite differentiated yarn, the resulting fabric can be tailored to suit specific needs. Whether for fashion, industrial use, or medical applications, composite yarns offer versatility that traditional yarns simply cannot match. This adaptability makes them highly sought after in various markets, from clothing manufacturers to medical fabric developers.

How Composite Differentiated Yarn Works

The manufacturing process of composite differentiated yarn involves carefully selecting and combining different fibers to achieve the desired characteristics. The fibers may be spun together in various ways, such as through twisting, plying, or other methods, to ensure the final yarn has optimal strength, texture, and performance properties.

This combination allows the final product to leverage the strengths of each fiber type. For example, a blend of polyester and cotton can provide the breathability of cotton along with the strength and moisture-wicking properties of polyester. The differentiated fibers work together synergistically, creating a fabric that excels in areas where traditional fabrics fall short.

Applications of Composite Differentiated Yarn

Composite differentiated yarn is used in a variety of industries where fabric performance is critical. Below are some of the key areas where this innovative yarn plays an essential role:

| Application Area | Key Benefits | Examples |

|---|---|---|

| Sportswear and Activewear | Moisture-wicking, elasticity, durability | Running shirts, yoga pants, athletic jackets |

| Outdoor and Workwear | Enhanced abrasion resistance, weather protection | Hiking gear, durable work jackets |

| Automotive Upholstery | Resistance to wear, UV protection, and comfort | Car seat covers, interior trim |

| Medical Textiles | Biocompatibility, comfort, and durability | Surgical gowns, bandages, compression garments |

| Home Furnishings | Strength, flexibility, and resistance to stains and wear | Sofa upholstery, curtains, cushions |

In each of these applications, composite differentiated yarn provides distinct advantages over traditional yarns, making it a preferred choice for manufacturers and designers who require enhanced durability and performance from their fabrics.

Performance Enhancements: Key Features of Composite Differentiated Yarns

| Feature | Description | Benefit |

|---|---|---|

| Abrasion Resistance | Yarns designed to withstand repeated friction | Longer-lasting fabrics in high-wear areas |

| Moisture Management | Yarns blended with moisture-wicking fibers | Keeps the wearer dry and comfortable |

| Elasticity | Inclusion of spandex or other stretchy fibers | Fabric stretches and recovers, offering flexibility |

| UV Protection | Fibers treated to resist UV rays | Protects fabrics from fading and damage from sunlight |

| Lightweight Construction | Use of lightweight fibers like polyester | Fabrics remain strong but light in weight |

Challenges and Considerations

While composite differentiated yarn offers numerous benefits, it is important to consider certain challenges:

- Cost: The production of composite differentiated yarn may be more expensive than traditional yarns, primarily due to the added complexity in the manufacturing process and the variety of materials used.

- Compatibility of Fibers: Not all fibers blend well together, and achieving the right combination requires careful experimentation to ensure that the resulting yarn performs as expected in terms of durability, flexibility, and comfort.

- Environmental Impact: As with any synthetic material, the environmental impact of composite yarns is a growing concern. Manufacturers are increasingly looking into ways to produce eco-friendly versions using biodegradable fibers or recycled materials.

Conclusion

In conclusion, composite differentiated yarn is a revolutionary product that enhances the durability and performance of fabrics across various industries. By combining different types of fibers, manufacturers can create fabrics that are stronger, more flexible, and more comfortable than ever before. Whether in sportswear, automotive textiles, or medical applications, the potential of composite differentiated yarn is vast, offering solutions for a wide range of performance requirements.

The unique blend of materials in composite differentiated yarn allows for superior performance under various conditions, including better moisture management, increased durability, and resistance to wear and tear.

FAQ

Q1: What is the difference between composite differentiated yarn and traditional yarn?

Composite differentiated yarn blends multiple fibers to enhance the fabric’s strength, flexibility, and moisture management, while traditional yarns typically consist of a single fiber type.

Q2: How does composite differentiated yarn improve fabric durability?

The combination of different fibers in composite yarn makes fabrics more resistant to abrasion, wear, and damage, significantly extending their lifespan compared to conventional yarns.

Q3: Can composite differentiated yarn be used for all types of fabrics?

Yes, composite differentiated yarn is versatile and can be used in a wide range of fabrics, including those for sportswear, workwear, medical textiles, and upholstery.

Q4: Is composite differentiated yarn more expensive than traditional yarn?

Yes, the cost of composite differentiated yarn is typically higher due to the complexity of its production and the variety of fibers used.

Q5: Are there eco-friendly options for composite differentiated yarn?

Manufacturers are increasingly exploring eco-friendly options, such as using biodegradable or recycled fibers, to reduce the environmental impact of composite yarn production.

+86-0571-82795522

+86-0571-82795522

LANGUAGE

LANGUAGE

English

English